Welding

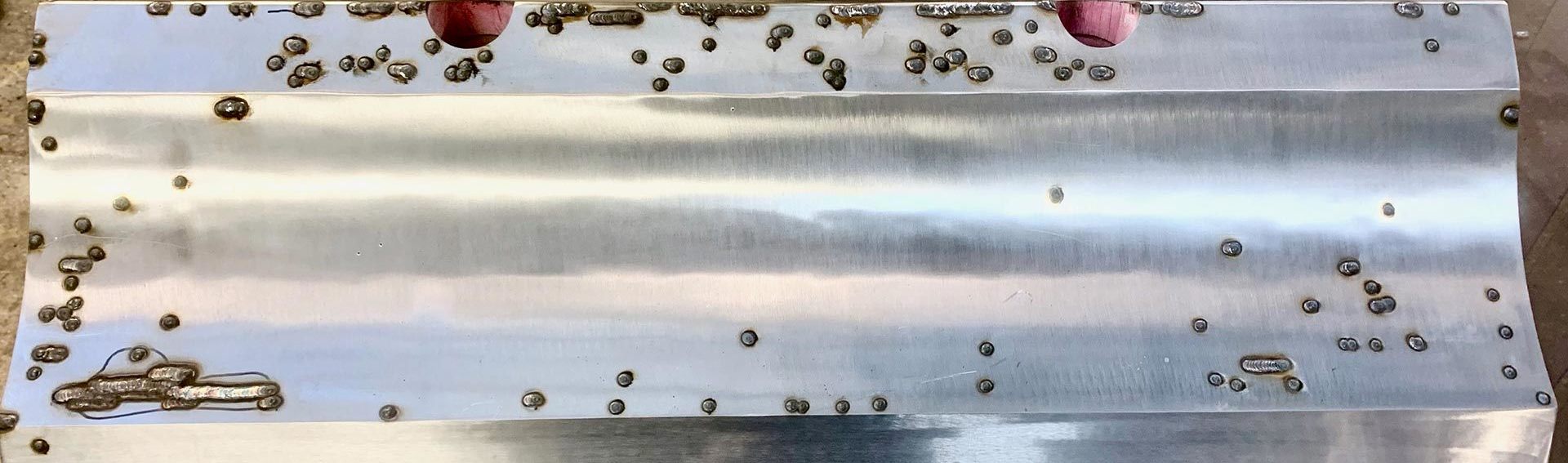

Here at Reddish Electroplating we have added MIG & TIG welding as a necessity to the chrome plating of new cast / hard welded / fabricated items as well as most repair items. We have found that some items that we receive for chrome plate will require a little (or in some cases, a lot) of remedial filling in prior to chrome plate to prevent blow / pin holes in the finished chrome plated surface.

Components will undergo pre-chrome preparation by either pre-polishing, pre-grinding, vapour grit blasting or a combination of some or all. Once at this state we can crack / defect detect using a 3-part dye penetration process. Once defective areas are located we can TIG weld using a suitable fill material to compliment the parent material, blend and re-test. We have a varied selection of filler materials and access to valuable data regarding pre-heating, filler types to prevent deflection and or further cracking, cooling times etc where applicable. No items will be welded or heated without prior notice to the customer for consent and to agree a procedure.

Some machine components can be brought back to a useable condition even if you may have thought they were at the end of their lifespan. A lot of mixing machine components, hydraulic units, feed screws, pump rotors etc are very expensive to manufacture so if they can be repaired at a fraction of this cost then it is an invaluable service for us to offer. For this we may use MIG, TIG, MMA or a combination of some / all depending on the severity of the erosion / wear. Again, all will be clarified with the customer prior to commencing.

It is worth an enquiry to check the feasibility of this method before replacing the item. It may save you a lot of time and money.